| Sign In | Join Free | My webtextiles.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My webtextiles.com |

|

Brand Name : Joiner

Model Number : ZME 18/72A

Certification : ISO9001

Place of Origin : Sichuan,China

MOQ : 1 piece

Price : USD10

Payment Terms : T/T ,L/C

Supply Ability : 5000piece/year

Delivery Time : 30-60 days

Packaging Details : Wood

Material : CPM 9V

Heat treatment : Vacuum quenching

surface treatment : Sand blasting

Application : Twin screw extruder

Screw design : Double screw

Function : Mixing

Standard : GB/ DIN etc.

Technics : CNC Machining

Warranty : 6 months

Condition : New

Material hardness : HRC58- 62

Feature : Wear resistance

1. Introduction of products

| Name | Profile | Shear unifromity | Elongatinal micing aboility | Dispersice nature | Cleaning action | Wetting action | Usage |

| ZME |  | high | high | high | low | high | General mixture |

2. Materials:

※For wear application:

Tool steel: W6Mo5Cr4V2

PM-HIP materials: SAM10, SAM26, SAM39, CPM 10V,CPM9V.

※For corrosion application:

Nitrided steel: 38CrMoAl

PM-HIP materials: WR4, SAM26, SAM39, CPM 10V,CPM9V.

※For wear and corrosion application:

PM-HIP materials: SAM26, SAM39, CPM 10V,CPM9V

※Other materials:

304, 316L, C276 etc.

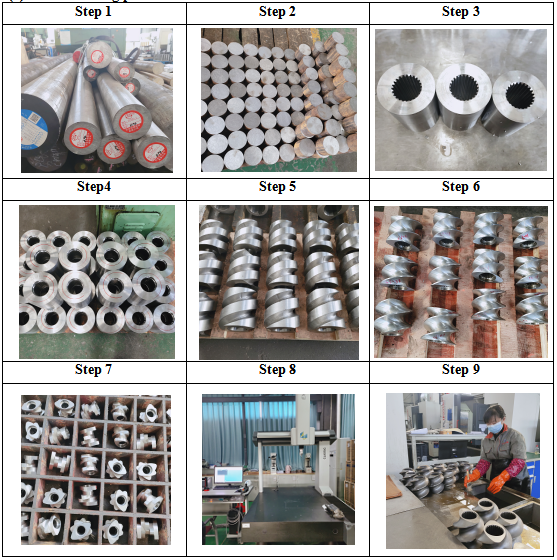

3. Standard production process:

4. Heat treatment

As we all know, heat treatment is very important in the screw production process. In order to ensure the quality of products, Joiner has purchased professional heat treatment equipment to produce, so that we can control the construction process by ourselves.

5. Processing Route Tracking List

Each process requires inspection . The production personnel shall check whether it’s meet the requirements of the drawings by themself. If it meets the requirements of the drawings,it shall be submitted to the inspection personnel for inspection. After pass the inspection to the next process personnel processing.

6. Packing Details

Standard packing of paper boxes and wooden boxes.

To product antirust processing ,and then use the paper package,bubble,fixed in the wooden case,after confirm the delivery.

7. Products photos

|

|

Model 95 ZME- Zahunmisch Mixing Screw Elements Plastic Extruders for Puffed Food Factory Images |